Jedan od gorućih problema stomatologije je kako eliminisati duge i neprijatne zahvate koji pacijenta vezuju satima za stolicu. Izrada zubnih krunica je deo većine zahvata koje obavljamo u Ordinaciji Cvejanović i svaki pacijent do sada je morao da se podvrgava veoma neugodnoj proceduri uzimanja otiska zuba gipsom i potom čeka nekoliko dana na krunice.

Srećom, to je sada prošlost!

Nema više bolnog razvlačenja usta kako bi se uzeo otisak, nema više dvostrukih i trostrukih proba i korekcija krunica, nema više mučnine koju proizvodi gips u ustima, nema više čekanja!

Ordinacija Cvejanović uvrstila je u svoj arsenal najmodernijih uređaja i fenomenalnu CEREC (CEramic REConstruction) mašinu, koja omogućava digitalno uzimanje otisaka i proizvodnju krunice na licu mesta u ordinaciji za samo pola sata! Osim krunica, CEREC metodom prave se i plombe, mostovi i keramičke fasete.

Procedura izrade krunice počinje skeniranjem, koje je potpuno neinvazivno i traje samo nekoliko sekundi, a model zuba i buduće krunice odmah je moguće videti na ekranu računara. U slučaju da posumnjamo da skeniranje nije bilo kompletno ili da se pacijent pomerao, lako je ponoviti postupak, dok kod tradicionalne metode ponovjleno uzimanje otiska predstavlja izuzetan napor i fizički je veoma neprijatno i za lekara i za pacijenta.

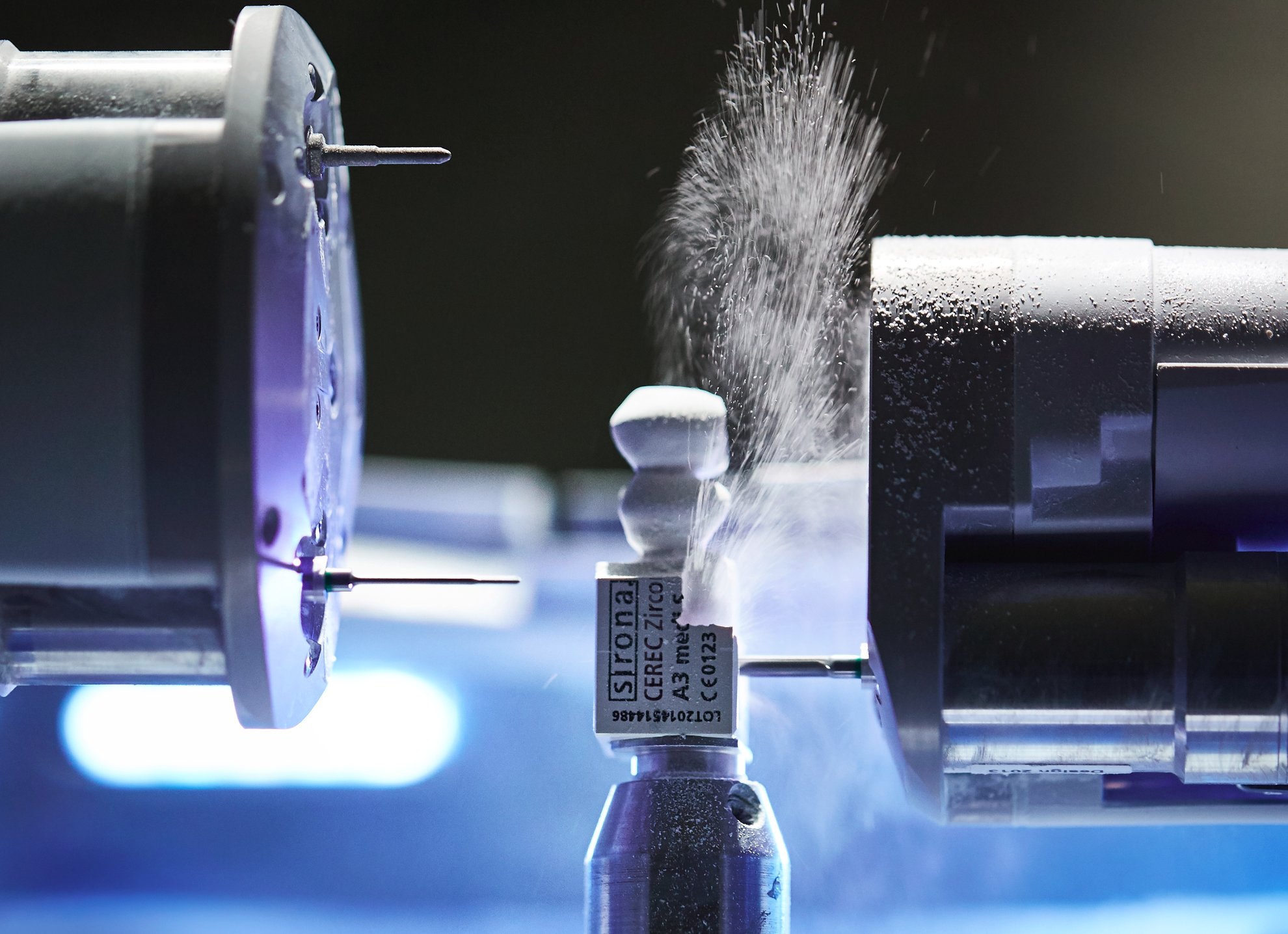

Zatim, pomoću softvera koji je deo CEREC sistema, frez mašina od keramičke kockice izrađuje krunicu pred očima pacijenta za samo nekoliko minuta, dok se ranije model slao u laboratoriju za izradu krunica (čekanje nekoliko dana) ili se krunica pravila u ordinacji (čekanje dan ili dva), pri čemu bi pacijent dok čeka često u ustima imao samo manje delove zuba koji su predviđeni da nose krune, što je psihički najneprijatniji deo terapije, dok je prilikom ugradnje implanata pacijent mogao da dobije privremene krunice, ali to je predstavaljalo dodatni trošak.

Kada krunica izađe iz frez mašine pristupa se njenoj obradi i poliranju, nakon čega se odmah cementira u ustima pacijenta, a kompletan proces od skeniranja do prvog zagrižaja traje samo 30 minuta.

Osim udobnosti, psihičkog mira i uštede, prednost izrade CAD CAM CEREC sitemom je u neverovatnoj preciznosti naleganja bilo koje nadoknade i zubne krunice, faseta i keramičkih inleja. Samim postupkom digtalnog skeniranja i modelovanja preskače se više nepotrebnih faza pri izradi krunica i time ima manje prostora za grešku. Koliko god dobar zubar bio, vrlo je verovatno da krunica izrađena na standardni način neće biti savršenog oblika već samo približno savršena, tj. vršiće svoju funkciju ali neće biti maksimalno udobna, efikasna i lepa, dok se CEREC metodom postiže apsolutna perfekcija.

Naredna značajna prednost CAD CAM CEREC sitema je to što se zubne krunice izrađuju od pune keramike, odnosno od gotovih keramičkih blokova. Kao što se više cene laptopovi i mobilni telefoni čije je kućište od jednog komada aluminijuma, tako su i monolitne keramičke nadokande, kod kojih je cela zubna krunica od istog komada keramike, daleko čvršće od onih koje su izrađene kombinovanjem keramike i metala ili keramike i cirkona. Veza između dva materijala je najslabija karika u krunici i tu dolazi do pucanja i odlamanja kermaike, zbog čega se u savremenoj stomatologiji sve češće nadoknade izrađuju od pune kermimke.

CEREC mašina krunice pravi od keramičkih blokova

Jedino ograničenje CEREC tehnike je povremena potreba da se krunica oboji drugačije od boje originalne keramičke kocke, međutim to je proces koji traje samo jedan dan i potreban je isključivo kod estetski najzahtevnijih zahvata i kod zuba u prednjoj zoni. Takođe, nije u svakom slučaju moguće izraditi krunicu za implant u CEREC mašini, iako ova tehnika značajno ubrzava izradu krunica za kompletan implantski rad jer smanjuje na minimum broj krunica koje moraju ručno da se rade.